Sodium hypochlorite mainly works by generating hypochlorous acid though hydrolysis, and the hypochlorous acid will decompose nascent oxygen further, whose strong oxidation will denature the protein of the virus and other substance, it leads to kill pathogenic microorganism. What's more, hypochlorous acid can not only act on cell wall, virus’s outer shell, but also on the body of the virus and conduct oxidation reactions with nucleic acid, enzyme and other organic polymers as it has a small size and is uncharged, thus killing pathogenic microorganism. Besides, the chlorine generated from hypochlorous acid can significantly improve the osmotic pressure of the bacteria and virus, resulting in loss of activity and death.

The most widespread disinfectant used in the

treatment of drinking water, circulating water is chlorine, which can be applied in a variety of ways. History has taught us that, in bacteriological conditions, chlorinating water is a quite safe way of disinfecting drinking water, after all, more than 75 years have passed since chlorine was used to chlorinate drinking water for the first time. Many years of experience have shown that acute toxicity can be excluded, when chlorination is executed correctly.

With

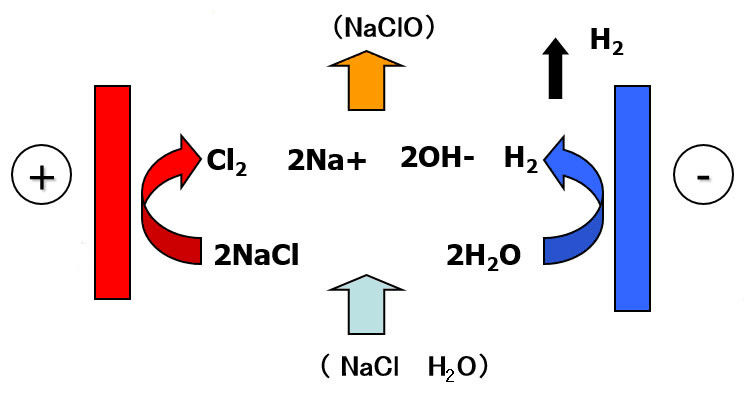

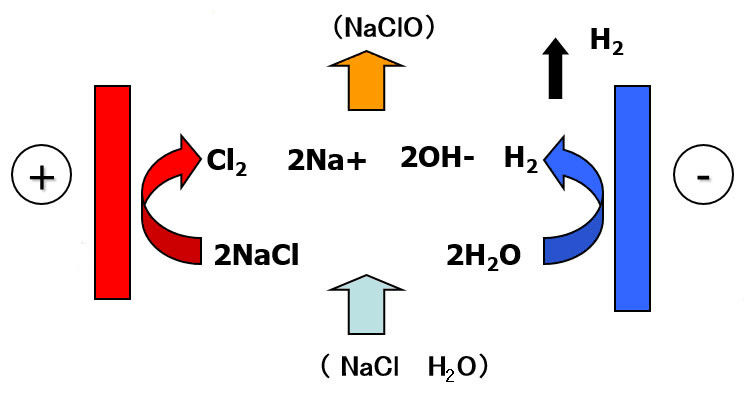

electrolysis, chlorine is produced directly from a solution of common salt using electricity.

NaCL+ H2O + Electricity = NaCLO + H2↑

Or

Salt + Water + Electricity = Sodium hypochlorite + Hydrogen gas↑

The electrolytic process of electrolyzing NaCl solution. Sodium hypochlorite generator is a process of electrochemical reaction. The only two materials required are water and salt; no additional material is needed. The sodium hypochlorite solution produced is very pure. As this system is applied to disinfection of tap water, the design of the generator system has fully considered the characteristics of energy-saving operation, cost saving, high reliability, long service life, easy operation, etc.

Advantages of MCT Electrochlorination system

On site generation is a proven, cost-effective, reliable and safe alternative disinfection treatment method. The use of on site generated sodium hypochlorite reduces the formation of disinfection byproduct and improves water quality. The process also offers other advantages as following:

-

Production of required volume

Efficient, stable disinfection that can be produced on site in required quantity and concentration( from 0.1% to 0.8%).

Waste free production with environmental-friendly raw material: salt, water and electricity. NaOCl solution concentration up to 1.0% is not considered as hazardous material and will disintegrate in its natural components.

-

High profitability and independence

Saving chlorine supplier, storage, reduction and safety cost. Independent from delivery possibility of the chemical industry.

Control of the complete technological process with a central PLC control system. Visualization of the entire process and logging of all key parameters of alarms. Any parts of the process of the system could also be adjusted by PLC.

Applying with on site electro chlorination system could greatly reduce the operator to help users reducing the cost and other safety maintenance related cost.

Element chlorine is a dangerous chemical, it is harmful to human body like respiratory tract and retina or even death. On site generation with MIS electro chlorination system could prevent operator directly touches the chlorine or other strong acid and alkali for protection.

Application

Please click below application to related industries you interested to.

applicatioin