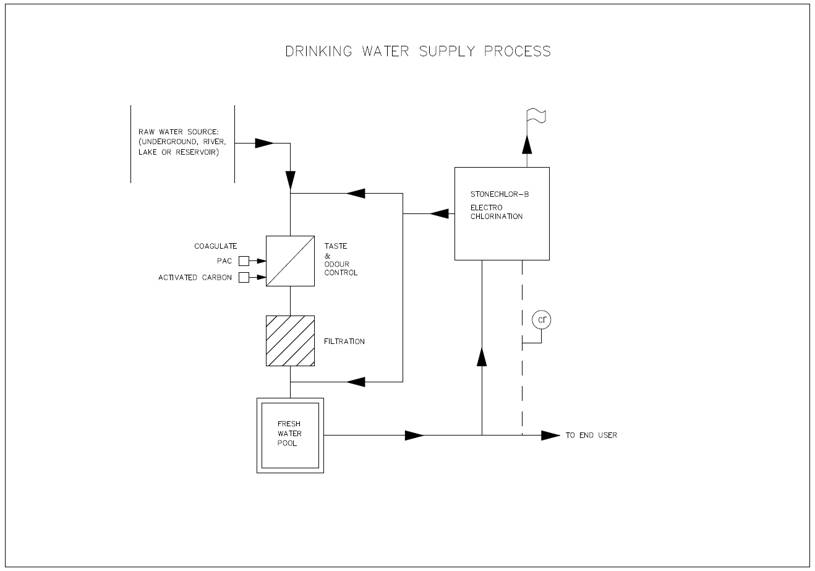

Drinking Water Supply

Description

Surface (Lake, river, reservoir) or underground water contains various microorganisms, bacteria and algae that would cause serious disease or fever. Also those microorganisms, bacteria and algae that would contributes to a biofilm formation on the membrane surface. A biofilm is a bacteria colony that grows on a designated surface where a carbon source and nutrients are available. Killing bacteria and microorganism before entering the membranes will prevent bio fouling.Disinfection is one of the vital process in drinking water supply, unlike other types of disinfection methods, residual chlorine in the pipeline could be able to have continuous disinfection function while fresh water comes out and distribute to the resident. Milestone Chlorination Technologies developed brine electro chlorination system for drinking Water & Industrial sewage treatment application, it is the safest and economic alternative for water works to disinfect drinking water rather than bulk Sodium Hypochlorite delivery and chlorine gas.

Milestone Chlorination Technologies LLC has years of water treatment engineering experiences, which could be able to allow us to provide unique solution utilize our own chlorination system. Parallel Plates Electrolyzer with acid washing packages for electro chlorination system will be applied for drinking water supply industry to achieve capital and operation cost effective, also for raw material as salt which client could control the contents of the chemical well in order to achieve healthy consideration.

Process Flow

The fresh water goes into the package through the water softener to eliminate calcium and magnesium in it, the solid salt (NaCl) pulls into salt saturator mixed with fresh water becomes saturated brine, the saturated brine pump delivers the saturated brine and the fresh water pump transfer the fresh water mixed with saturated brine mixed into diluted brine (2.0% to 3.5%), the diluted brine goes into the electrolyzer assembly, which has DC power supplies by the transformer rectifier to it.The rectifier for small and normal capacity we designed is using switch mode, which is more cost effective and small foot print, also the rectifier is specifically for the requirements of the installed electrolytic cell. It converts the AC platform input voltage into the required low voltage DC current and regulates this output to a selected and controlled level.

Electrolysis process takes place within the electrolytic cell as per the following equation:

At the anode: 2 Cl - 2 e → Cl2

At the cathode: 2 Na+ 2 H2O + 2 e→ 2 NaOH + H2

Overall: 2 NaCl + 2 H2O → 2 NaOCl + 2 H2

Through the electrolysis process the package produces the required amount of sodium hypochlorite together with the by-product, hydrogen gas.

The solution with hydrogen gas are fed into degassing tank and the hydrogen gas will be pushed out by air blowers connected with the storage tank to vent to open atmosphere.

The hydrogen free solution containing sodium hypochlorite is then dosed into the dosing point through dosing pumps or gravity at certain pressure.

English

English