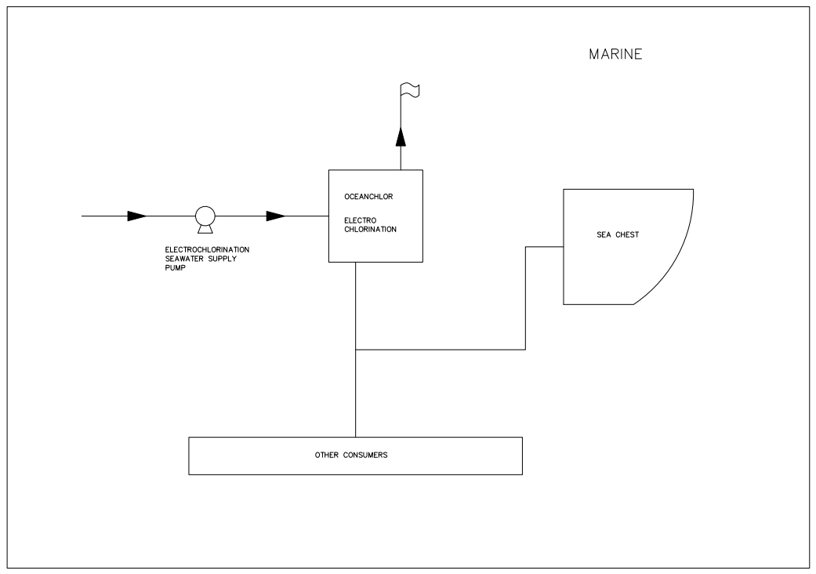

Marine

Description

The perpetual growth of sea life within a cooling system can cost even small vessels tens of thousand dollars a year. Mollusca, algae slime and weed not only constrict the flow of cooling water to the heat exchanger surfaces, they also hasten localized corrosion by restricting oxygen diffusion, and cause destructive turbulence at inlets which can severely shorten the life of affected components. In the general and progressive loss of vacuum, and hence of fuel-efficiency which results from a steadily fouling circuit. By eliminating fouling, ships can save on fuel costs as well as making incalculable savings on maintenance.Electrochlorination offers a final and comprehensive solution to the problems of marine fouling throughout the shipboard cooling system. OceanChlor series electro chlorination package specifically developed and customized design skid for ship board applications and its best electrolysis performance, supreme engineering and long, low maintenance, long life span are generally acknowledged to be unsurpassed.

Milestone Chlorination Technologies LLC provides unique design of Concentric Tubular Electrolyzer (CTE) based electro chlorination package system (on site sodium hypochlorite generator), Concentric Tubular Electrolyzer with platinum coating could achieve the highest efficiency of electrolysis process, Concentric Tubular Electro chlorination system is using high velocity to achieve self-cleaning technologies, which could save the cost and troublesome from acid washing system and potential hazardous caused by the hydrochloric acid (HCl).

Process Flow

Raw seawater as the battery of the package fed into the package inlet at the designed flow rate, the seawater goes through seawater booster pump and strainer to purify it for downstream usage.The seawater flow rate controlled by the electrical operated valve, certain required flow rate is passed through the electrolytic cell which are fed an electrical supply from the package transformer rectifier.

The rectifier is designed specifically for the requirements of the installed electrolytic cell. It converts the AC platform input voltage into the required low voltage DC current and regulates this output to a selected and controlled level.

Electrolysis process takes place within the electrolytic cell as per the following equation:

At the anode: 2 Cl - 2 e → Cl2

At the cathode: 2 Na+ 2 H2O + 2 e→ 2 NaOH + H2

Overall: 2 NaCl + 2 H2O → 2 NaOCl + 2 H2

Through the electrolysis process the package produces the required amount of sodium hypochlorite together with the by-product, hydrogen gas.

The solution with hydrogen gas are fed into degassing tank and the hydrogen gas will be pushed out by air blowers connected with the storage tank to vent to open atmosphere. Besides the storage tank, Milestone Chlorination Technologies LLC also could provide unique design of cyclone degassing separator to separate liquid and gas.

The hydrogen free solution containing sodium hypochlorite is then dosed into the dosing point through dosing pumps or gravity at certain pressure.

English

English