The purpose of on-site generation sodium hypochlorite solution from salt water is to economically and safety produce this powerful biocide and disinfecting agent for industrial plant using. Brine based electro chlorinator is generally applied for water plant treatment, drinking water disinfection, and being widely applied for the reason of its economic operating cost, as the raw material is easily find locally.

The electrolytic process of electrolyzing salt water type sodium hypochlorite generator is a process of electrochemical reaction. The only two materials needed are water and salt; no additional material is needed. The sodium hypochlorite solution produced is very pure. As this system is applied to disinfection of tap water, the design of the generator system has fully considered the characteristics of energy-saving operation, cost saving, high reliability, long service life, easy operation, etc.

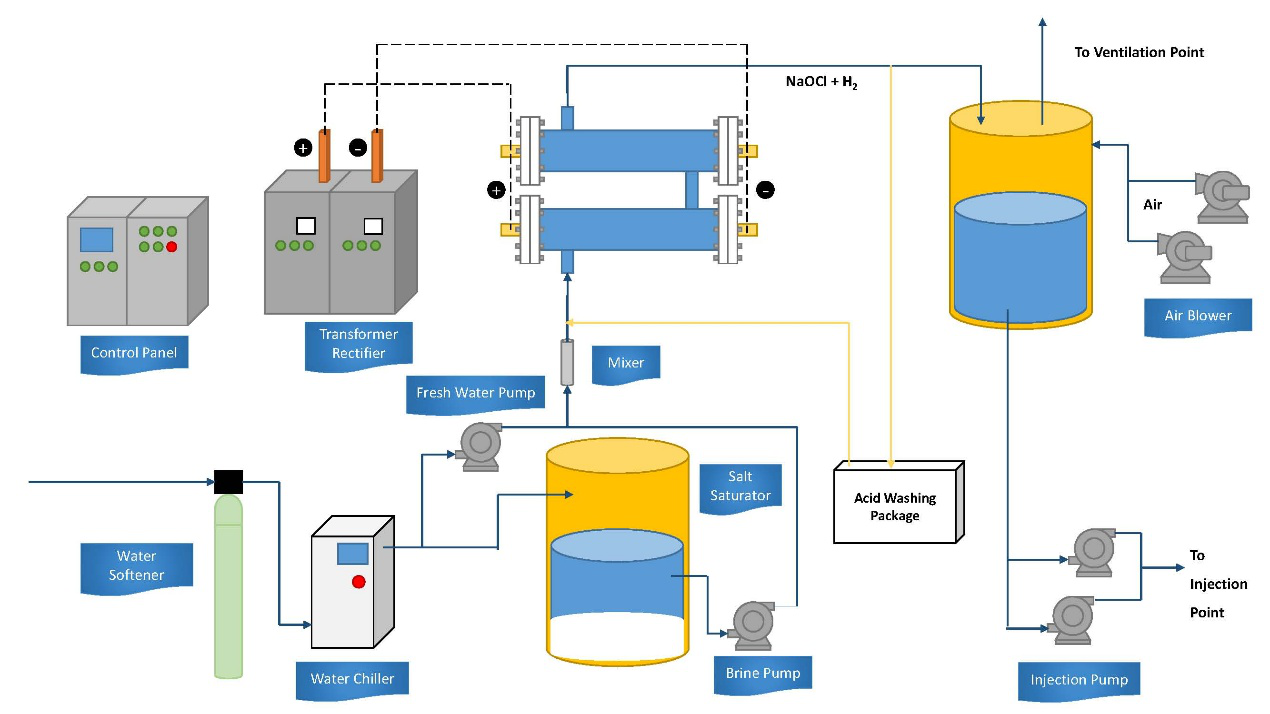

Component of Seawater Electrochlorination

- Water Softener

- Water Chiller (Option)

- Salt Saturator

- Transfer pump (Brine and Fresh water)

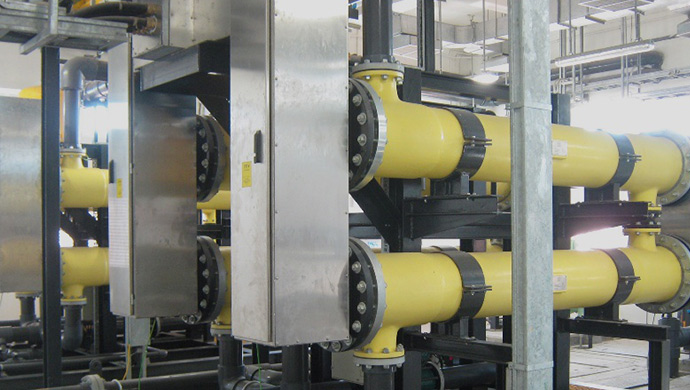

- StoneChlor – B Electrolyzer Assembly

- Transformer & Rectifier

- Local Control Panel

- Storage Tank

- Air Blowers

- Injection Pump

- Acid Washing Package

- Process Description

Pure industrial salt (NaCl without iodine) pull into the salt dissolver and being dissolved into saturated brine, and feeding into proportion inlet at the designed flow rate via a side stream from the main processing piping line.

Once controlled, the diluted brine is passed through the electrolyzer which are fed an electrical supply from the package rectifier.

Depending on flowrate available this diluted brine flow will be flow rated controlled or pumped to provide the optimum operating flow rate to achieve as high as 8,000 ppm available chlorine.

The rectifier is designed specifically for the requirements of the installed electrolyzers. It converts the AC platform input voltage into the required low voltage DC current and regulates this output to a selected and controlled level.

Electrolysis process takes place within the electrolyzer as per the following equation:

- At the anode: 2 Cl - 2 e → Cl2

- At the cathode: 2 Na+ 2 H2O + 2 e→ 2 NaOH + H2

- Overall: 2 NaCl + 2 H2O → 2 NaOCl + 2 H2

The solution with hydrogen gas are fed into degassing tank (Or cyclone degassing separator) and the hydrogen to vent to open atmosphere.

The hydrogen free solution containing sodium hypochlorite is then dosed into the seawater circuit through dosing pumps or gravity.

Technical Benefit of StoneChlor-B Electrochlorination System

|

Electrolyzer OEM |

On site Production |

|

Working with the China major anode and specialty coating manufacturer, we have access to the leading industry electrolyzers with over 30 years’ service.

|

Producing sodium hypochlorite on site reduces the requirement for use of liquid chlorine solutions. The impracticality of shipping, storing and dosing large volumes of bulk hypochlorite on offshore sites means electro chlorination is the industry preferred method of bio-fouling control. |

|

Safety |

Acid Washing |

|

Element chlorine is a dangerous chemical, it is harmful to human body like respiratory tract and retina or even death. On site generation with MCT electro chlorination system could prevent operator directly touches the chlorine or other strong acid and alkali for protection. |

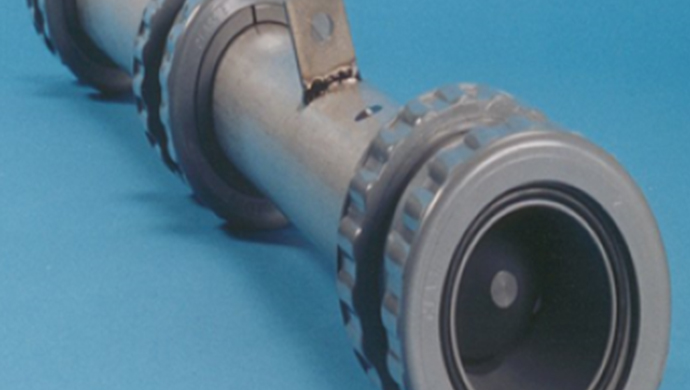

By applying acid washing technology for electrode to achieve long lifespan of the electrolyzers assembly.

|

|

Full Output Availability |

Process Automation |

|

By only supplying self-cleaning electrolyzer designs the packages do not require any scheduled downtime for cleaning. This provides the opportunity for clients to remove any duty/standby requirements for the electrolyzers and thus reducing footprint and cost effective. |

Control of the complete technological process with a central PLC control system. Visualization of the entire process and logging of all key parameters of alarms. Any parts of the process of the system could also be adjusted by PLC. |

Brine Electrochlorination Application

- Drinking Water Supply

- Desalination Plant

- Swimming Pool

- Hatchery

we will contact you within 24 hours.

English

English