Secondary water supply refers to the water supply form in which the tap water supplied by a water plant is stored in the water storage equipment after treatment and transferred to the user through pressurized facilities and water purification facilities. Nowadays, most high-rise buildings are directly related to the water quality and safety of secondary water supply, and are closely related to daily public life.

Although the traditional "water tank - water pump - water tank" combined with the secondary water supply system can solve the problem of water supply pressure and water supply, but the water stored in the water tank is more prone to secondary pollution. Therefore, new secondary water supply technologies were developed. Such as frequency conversion superimposed water supply system. It is a kind of secondary water supply equipment that can be directly connected with the water pipe network and has no side effect on the water pipe network.

What are the commonly used ways of disinfecting drinking water?

Commonly used drinking water disinfection method can be divided into physical disinfection and chemical disinfection. Physical disinfection is mainly through ultraviolet radiation, and chemical disinfection according to the type of disinfectant can be divided into chlorine disinfection and ozone disinfection. Among them, chlorine disinfection is the main disinfection way of centralized water supply, according to the difference of disinfection principle, can be divided into disinfection of free chlorine and disinfection of combined chlorine. The main chlorine-containing disinfectants include monochloramine, dichloramine, chlorine dioxide and sodium hypochlorite, etc. Ozone disinfection is a strong oxidant ozone disinfection. In order to improve the disinfection effect of drinking water, different disinfection methods have been used together to disinfect drinking water in recent years.

At present, sodium hypochlorite generator disinfection process is used to disinfect drinking water in a centralized water supply plant in urban and rural areas of China.

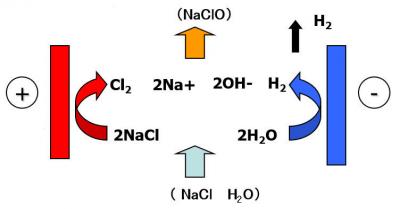

Electrolytic salt disinfection equipment hatchery sodium hypochlorite adopts low concentration salt water as electrolyte and adopts gravimetric method for determination. The operation of the electrolytic chlorine system is relatively simple and easy to operate, and the process mainly includes the following steps: first, water flows through the water softener to reduce hardness, reduce electrode scaling, and extend the cleaning interval; Secondly, salt is dissolved in the softened water tank to form a concentrated salt solution. The diluted salt solution flows through the electrolyzer; The electrolyzer then USES the direct current provided by the rectifier to electrolyze the diluted salt solution into sodium hypochlorite solution. Then the sodium hypochlorite solution flows into the storage tank. The metering pump pumps sodium hypochlorite into the disinfection treatment facility. Hydrogen, a by-product of the process, is then released safely into the atmosphere. The birth of hatchery sodium hypochlorite changes the traditional way of adding medicine in the past, reduces the usage of sodium hypochlorite solution, reduces the working strength, increases the service life of the equipment, saves the power consumption, and is more safe, economical and reliable.